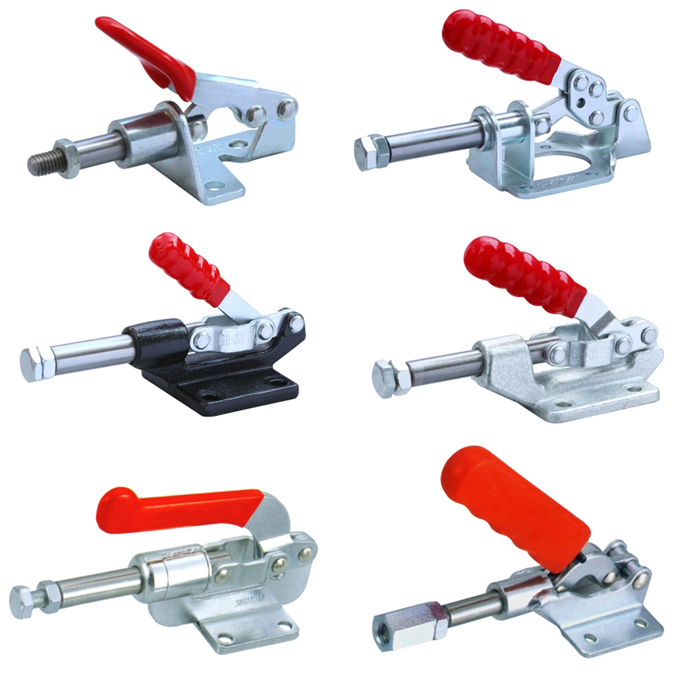

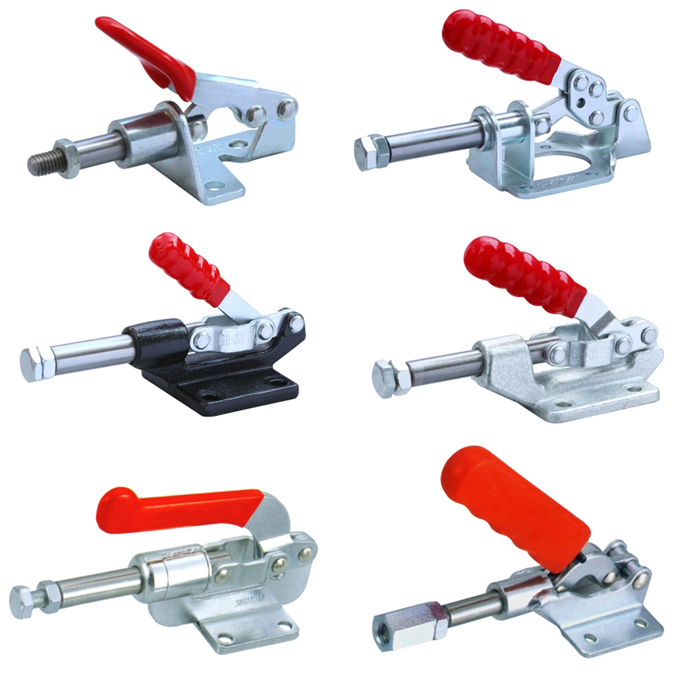

Toggle Clamps Manufacturer

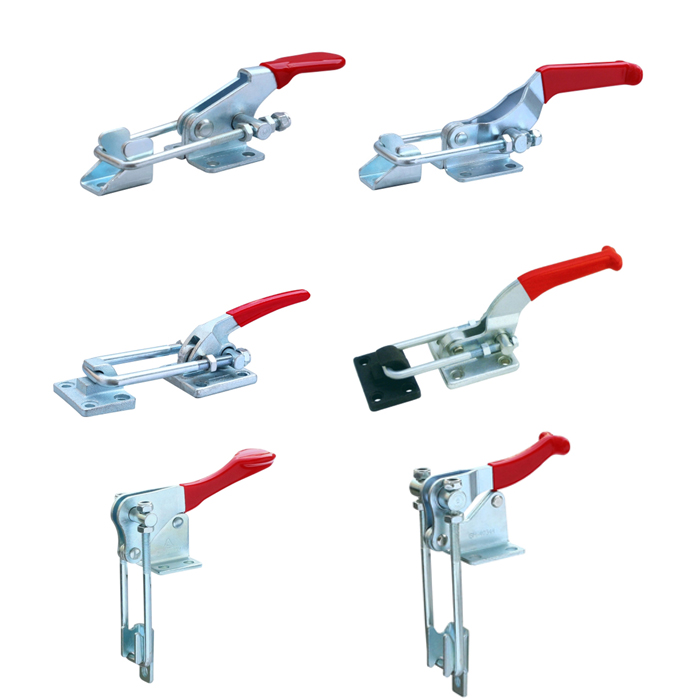

- Great Performance, Highly Adjustable, Low Maintenance

- Material: Steel/Stainless steel

- Holding Capacity: 210-3500Kg

- Oil and Stain resistant red vinyl hand grips

- Adjustable clamping force

- Plastic cover handle for easy, safe and comfortable operation

- Ergonomic paddle for smooth operation

- Variety of design and holding capacity

- Widely used on sealing chambers, lids, machine operation, welding, jigging, repairing, electronic equipment assembly, etc field.

Your Professional Toggle Clamps Manufacturer In China

Want to know the different features of toggle clamps? Read below to find out.

Cost Saving

Tooling costs are lessened as tool design and tool making turn out to be much simpler. Lowered cycle period lowered with low maintenance. What’s more, reduced production expense through raising productivity

Low Maintenance

Such clamps are nearly maintenance free. Occasionally, fewer drops of lubricating oil are all that is required to keep them in a great working state.

Durability

Did you know that each vital parts of a toggle clamp are zinc and hard plated? That offers sufficient wear and corrosion resistance that guarantees a longer working life.

Versatility

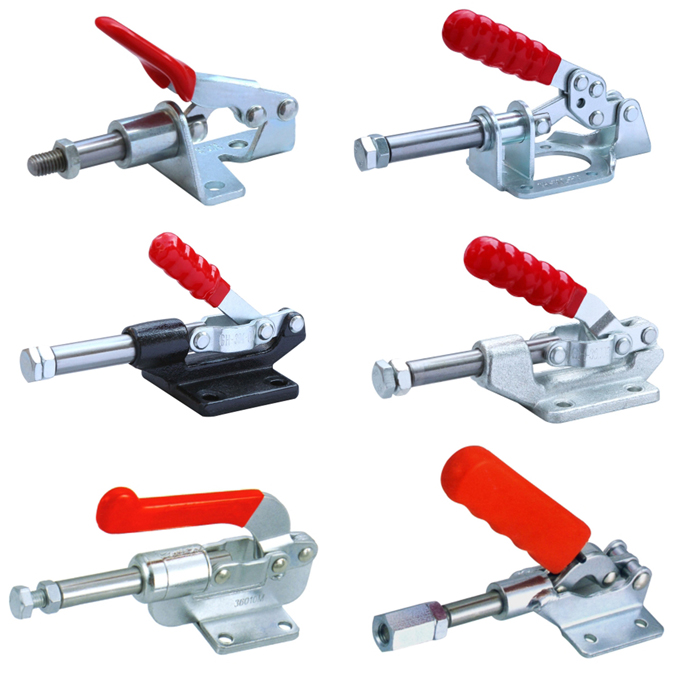

Another great feature of a toggle clamp is that they are accessible in different types. Some of this includes vertical toggle clamp, horizontal toggle clamp, push pull toggle clamp, pneumatic toggle clamp, and lastly, latch type toggle clamp.

Simple to Integrate

There’s no added accurate slotting, machining and others is required while employing such clamp in any tooling.

Time-Saving

In case you didn’t know yet, the clamping and release action of a toggle clamp is obtained in seconds. That offers massive time saving every cycle.

Great Performance

A toggle clamp excellently performs if compared to several types of clamps. You see, its application is unique, so they might not get as much attention as other types of the clamp. Purchasing a toggle clamp is your last resort. However, once you are buying, you’ll realize what an ideal option you’ve made. That’s because they save you from straining your hand and offer safety.

Reliable

A toggle clamp is considered very simple to use and reliable. Apart from that, it’s an incredibly efficient operating system makes it cost-effective and lowers work time. No industry would mind the investment on this little thing that would bring efficiency.

Highly Adjustable

What’s more, a toggle clamp is extremely adjustable as well and can be utilized to fit your work. You can make use of them as a handhold. You can exert the coveted clamping force on the item being worked on. You can also employ them in rough work regions and adjust it to different heights. Now, how can you beat that?

Flexible

Find a toggle clamp that is accessible in different materials and designs which fit your needs. Those also come with various handle placements and designs as well as pressure ratings and you could get one who comes in helpful to you.

What is a Toggle Clamp?

Toggle clamp is also called quick clamp, over-center clamp, release clamp, and many others. In case you didn’t know yet, a toggle clamp is a fastening tool which generally composed of a handle to control the device.

It is a holding bar that is made to hold the workpiece, as well as a linkage arrangement of pivot pins and levers to increase the applied force. Once it is tied up, the toggle clamp becomes locked essentially. You see, a toggle clamp serves typically to secure an object tightly to avoid it from separating or moving inward pressure is applied.

Mostly, a toggle clamp is composed of the following parts:

The base for mounting at the workplace

Spindle for pressure adjustment

Linkages for multiplying the applied force

Clamping arm to reach the workpiece

Handle to operate

What’s more, toggle actions clamps work via a linkage system of pivots and levers. The fixed-length levers, linked by pivoting pins, present the clamping and action force. The toggle action features a lock point that is a linkage and fixed stop. Once it is in the lock position, the clamp doesn’t close unless the linkage system is released or moved. Even though it’s oriented in various ways, the majority of toggle clamps are created with the help of a basic principle.

Types of Toggle Clamp

1.Vertical Toggle Clamps

Vertical toggle clamps are determined through their vertical handles. Such clamps are produced with holding capacities of approximately 5,000lbf. The clamping bar exhibits approximately 90 degrees opening angle for simple unloading and loading and could be solid or U shaped. Furthermore, the base is a flanged mounted or straight mount.

2.Horizontal Toggle Clamps

Horizontal toggle clamps are fast-acting hold-down clamps which feature a handle locked in a horizontal position. It rotates the handle of such horizontal toggle clamps down pivots that clamping arm is plunging in the opposite route. It locks over the center. This type of toggle clamp is produced with U-shaped or solid hold-down bars and along with different mounting options.

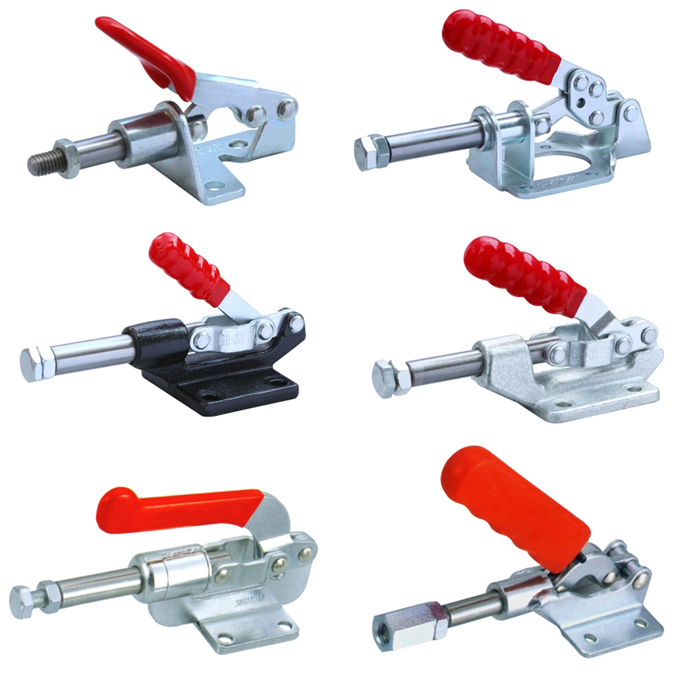

3.Push Pull Toggle Clamps

On the other hand, push pull toggle clamps integrate a sliding plunger to offer a straight-line clamping action. With this type of toggle clamp, the toggle action shifts and locks the plunger in either the pulling or pushing route.

4.Pneumatic Toggle Clamps

In case you didn’t know yet, pneumatic clamps employ air-actuated cylinders to work the clamping action. These are perfect for fast clamping in various production operations, and yet are very economical and portable to engage on those short-run jobs with brief fixturing.

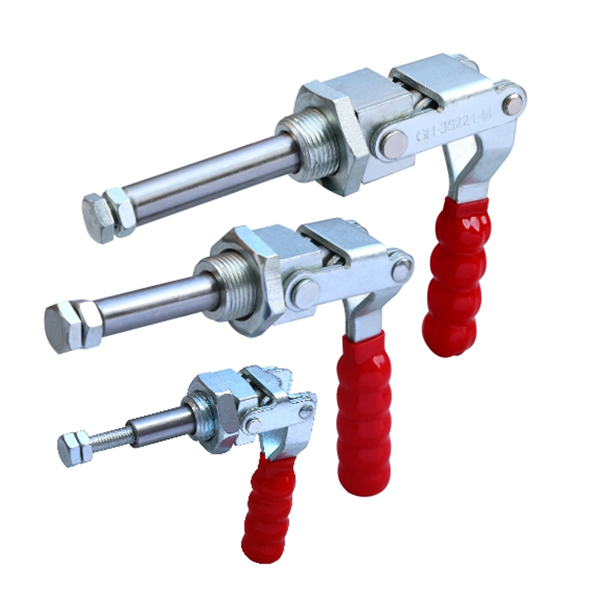

5.Latch Type Toggle Clamps

Lastly, latch type toggle clamps are types of toggle clamps which are compact in design and could be utilized to guarantee great holding capacities. If closing the spanner, a safety hook locks positively into the body. That stops the vibration-induced or inadvertent release from the clamping position. If you wish to open the safety hook, it’s unlocked per 1-hand operation.

There’s no doubt that a toggle clamp has a lot of benefits over other types of clamps. That’s mainly because some clamps enable some movement while clamping. On the other hand, a toggle action clap offers a more consistent and stable clamping point, could be produced from cheap materials, and are accessible in stainless steel for corrosive or outdoor applications.

So, are you in search of high-quality and reliable toggle clamps in the market today? There’s no need to look further because Roche Clamp got you covered! We have the best toggle clamps available in the market today. Contact us now!

Need Any Help

You tell us what you want, and we tell you what we can offer.

Your Guide to Choosing the Right Toggle Clamps

One of the most crucial devices in any household, toggle clamps are must-have in a homeowner’s stock. From keeping the things stationary while you work or holding down any object, toggle clamps work overtime to ensure everything goes as flawlessly as you need it to be.

You see, they are very multi-purpose tools which yield the highest clamping force, which makes it simpler to work. With the arm and handle in the similar axis, the vertical toggle clamp offers a lot of advantages with limitless functions to any person.

In this e-book, allow us to present you the basic and essential things you need to know when it comes to choosing the best toggle clamps for your needs. No matter what industry you’re in, this guide will surely help you.

Are you now ready? Let’s dive in!

What is a Toggle Clamp?

Toggle clamp is a basic mechanism that holds instantly. It is composed of a handle to operate, a clamping arm to reach the workpiece, a base for mounting at the workplace on its base and linkages for increasing the applied force.

A required clamping force is accomplished and exerted on the workpiece. Under that action, your toggle clamp holds the workpiece positively and firmly.

The reality that the clamp has one clamping plate denotes it’s utilized in conjunction along with the surface of the workbench to hold a workpiece safely. The plate of the toggle clamp thrusts on the workpiece, which holds it still, between the work surface and the plate.

The clamp employs a quick-action mechanism. That means it can be released or engaged in one fast movement. It works with a combination of pivot pins and levers that are connected. The lever is also utilized to distribute the clamping force, denoting if the lever is pressed down, the clamping plate thrust against the workpiece. Now, the clamp is locked and doesn’t unlock ‘til the lever is released.

A toggle clamp can be employed for both heavy-duty and light applications. Commonly, it’s widely utilized to hold workpieces in woodworking activities, like drilling and sawing.

There are many types of toggle clamps accessible today, some of which will be discussed in the next chapter.

Different Components of a Toggle Clamp

A toggle clamp is composed of various components.

1.Bolt Holes

A bolt hole is a place where bolts are positioned to fix the clamp to a worktop.

2.Pressure Adjuster

A pressure adjuster allows the clamping of various sizes of the workpiece to adjust the pressure even without the help of the operator.

3.Pivot Point

This is a pin located close the center of the clamp. A pivot point serves as a link between in the bar and the lever which clutches the clamping plate.

4.Lever

The lever has the role in controlling the movement of the clamping plate. Every time it’s pushed down, it engages the clamping plate through thrusting it against the workpiece and closing it in place.

5.Screw

The screw could be changed and relocated with the bar so it can be positioned at the finest position throughout clamping.

6.Clamping Plate

Ultimately, the clamping plate works in combination with a work surface to latch a workpiece in place. You see, it pushes against the workpiece to hold it still throughout clamping.

Different Types of Toggle Clamps

It is crucial that you determine the diverse types of toggle clamps that will be suitable for your project. Every one of them is accessible in an array of heights that enable the clamp to hold into various objects.

What’s more, they’re all capable of various holding capabilities, and some toggle clamps are transportable. You will find some that should be connected to a workbench. Those are all factors which must be taken into consideration if you are identifying the right type of toggle clamp you need.

The several types of toggle clamps are the following:

Vertical toggle clamps are the most sought-after and widely used in the engineering and manufacturing industry because they’re the most adaptable. They allow users to apply a low input force to make a high output clamping force. You see, the over-center locking mechanism stops the toggle clamp from opening within work holding.

That feature makes this type of toggle clamp perfect for routine holding while enabling a wide clearance for unloading and loading workpieces.

Compared to the hold-down bar and handle of the vertical clamps, horizontal toggle clamps move in the opposite direction. A horizontal toggle clamp is manufactured along with solid or a “U” shaped hold-down bars and with several mounting options.

On the other hand, latch type toggle clamps are clamps which employ a pull action to tighten. These type of toggle clamps might also be called as push clamps. They are perfect for fastening fixtures or doors, locking and latching.

Latching toggle clamps might be presented in vertical or horizontal configurations. What’s more, latch toggle clamps might need a detached fixed latch.

The push pull toggle clamps feature a plunger which transports in and out. Such clamps offer push and pull forces. The clamp might lock on either the pull or push position. They might also be known as straight line clamps or plunger-style clamps.

Pneumatic Toggle Clamps

You can use air-actuated cylinders to run the clamping device. They are perfect for fast clamping in routine production operations. These type of toggle clamps are available in different styles which includes:

retracting clams

hold-down and straight-line action

cylinders

It can easily retrofit a lot of manual clamps along with a pneumatic version, with the use of identical mounting patterns. Some of the benefits of using this type of toggle clamps are as follows:

Controllable and consistent clamping forces

Enhances ergonomics and safety

Can operate clamps remotely for those hard-to-reach regions

Lessens operator fatigue

Can operate clamps consecutively

Can operate various clamps at the same time

Boosts productivity

Improves cycle time

Toggle Clamp Working Principle: How Does Toggle Clamps Function?

Toggle action clamps run through a linkage system of pivots and levers. The fixed length levers, linked through pivot pints supply the clamping and action force. Toggle action has an over-center lock point that is a fixed stop and linkage. When it’s in the over-center position, the clamp can’t unlock or move unless the linkage is adjusted. Every type of toggle clamp has a similar action, only oriented differently.

Bear in mind that the toggle mechanism in clamp has three functions:

To rapidly close and open the clamp offering a maximum clearance in which to load and unload the workpiece

To make an over-center lock to avoid the clamp from releasing and opening the workpiece ‘til opened by the operator

To multiply applied load at the clamp handle into a high clamping force to hold the workpiece

Toggle Action Force Factors

The toggle action is the action of over-center clamp or toggle. Toggle clamps are composed of fixed length levers, that are linked with pivot pins. As the pivot pins come into line, significant forces are produced and once in the over-center position the clamp is closed, unless the linkage is transported. Thus, the benefits of toggle clamps are that they produce great clamping pressures because they come into the locked positions and they remain locked until detached.

There are two kinds of clap forces that you need to consider when understanding which toggles clamp to employ: clamping force and holding capacity.

Clamping Force

In case you didn’t know, the clamping force is the amount of force applied to the workpiece by locking and closing the clamp. Generally, it lessens the given holding capacity. The actual clamping force varies on a lot of factors which includes the clamps mechanical advantage, workpiece material, spindle cushioning, spindle height adjustment, and spindle position. In the majority of cases, approximately one-third of the given holding capacity could be applied through the hand with average effort.

Holding Capacity

The holding capacity stated for every clamp talks about the maximum force that the clamp can endure after being over-centered without damage to the clamp and with no toggle unlocking because of alteration of the clamp.

The over-center dimension is selected carefully in connection to the elasticity of the toggle clamp. That is to make the most of the clamping force while making sure that the clamp locks closed even if it’s under intermittent loading or vibration.

For those hold down clamps, the holding capacity is calculated through the spindle at the furthest end of the clamping arm. It will raise as the spindle goes nearer to the clamping arm.

Using Toggle Clamps

Toggle clamps weren’t made to deform materials but solely to hold the component. The suggested practice is to position parts against a fixed stop, so the clamp holds the piece in position. Therefore, any forces produced throughout the process will be applied during the fixed stop.

Under the clamping point, there must be enough support to avoid the item from moving and lessen deformation.

Here is a basic process on how to use a toggle clamp.

Fastening the Clamp

Before you employ a toggle clamp, you’ll require to attach it securely to a workbench. For you to do that, you’ll need a drill, four nuts, a pencil, and bolts.

Step 1. Mark the holes – With the use of a pencil, mark out the location on the work surface where you wish to fasten the clamp. You can employ the bolt holes on the base of your toggle clamp for some guidance. You must mark out four guide holes, 2 for every side of the clamp.

Step 2. Drill the holes – After you have marked the holes, you can employ the drill the create the holes in your workbench. You need to make sure that the holes are the appropriate size to suit the bolts.

Step 3. Attaching the clamp – For the next step, you need to position the toggle clamp, along with its bolt holes in arrangement with the holes on the work surface. When in position, you can insert the four bolts, one into every hole. For you to secure the bolts, put nuts on the ends and tighten them until the clamp is fixed securely.

Using the Clamp

When the clamp is attached to the bench top, it can be employed for holding objects still throughout work applications.

Step 4. Positioning the workpiece – You need to ensure that the lever of your clamp is pulled up. You need to guarantee that there’s space between the clamping plate of the tool as well as the work surface. Within that space, put the workpiece, so it’s opposite direction to the clamping plate.

Step 5. Pushing the lever – Push your lever on a downward position to engage the clamping plate along with the workplace and lock it in place. When the lever is pushed down, the clamp will lock automatically. That means the workpiece won’t be released ‘til the lever is pulled up.

There you have it. That is how simple it is to employ a toggle clamp. Your workpiece is now secure, denoting that your preferred application could be finished.

Applications of Toggle Clamp

Toggle clamps are considered over-center locking clamps. That means they are perfect for applications where the clamp is to be applied frequently. They are fast to use, much faster compare to screw fasteners and they latch into position once applied.

Because of the design of the linkage, a toggle clamp is most fitted to where there is less distinction in the thickness of the part (nevertheless this might be accommodated by any means) and where the highest force is needed at the end of the clamping effort.

How Industries Are Taking Advantage of Toggle Clamps

Many industries depend heavily on equipment to accomplish their tasks effectively. For that reason, toggle clamp is one of the most crucial tools which most industries must employ. Such clamps help to hold down a workpiece down and keep it stable. Thus, without being interrupted by repeated movements of the workpiece, that serves as a handhold while you work.

No doubt, the tool has a strong level and pivot system to operate appropriately. That aids a work to have the workpiece in complete control and do the tasks with no trouble.

Following are some obvious advantages which you can receive from using a toggle clamp:

Boost Overall Safety

Every time you’re working on an item, safety must be one of your primary concerns. The design of toggle clamps helps you get great safety, and the excellent locking action which comes with it is what helps to keep your tool and work securely in a place.

Such clamps are also efficient to subject wear and tear on the item you are working on now. Therefore, if you use such tools in your industrial circumstance for any goals, you’re able to perform your job effectively and safely.

Adds Flexibility

When we talk about selecting toggle clamp, you will find a lot of options accessible for you to choose from a selection. Mainly, if you’re planning to purchase a commercial toggle clamp, you will find that there’s a wide array of selection out there. Various aspects like pressure ratings, handle designs and handle placements that differentiate one from other toggle clamps.

A lot of toggle clamps are accessible that are made in different finishes for different uses. They could be availed of material which is corrosion resistant and as they last for a very long time. A few of the most typical varieties are accessible in nickel, plated, stainless steel and chrome finish.

Adds to Adaptability

A toggle clamp can adjust to workpieces of different heights. They’re accessible in models which can be employed in rough forgings and casting as well. Adjustable screws help an individual apply the needed clamping force on the item being worked on now. There’s a high exerting force along with such models, and so they can be employed in different circumstances.

They also come with great adjustability and so they can be employed as a handhold while operating with materials of different thickness.

Adds Productivity

It’s very fast and simple to install. That’s because there is excellent working dependability in the clamps. They are incredibly efficient, and so you can perform your work very faster and efficient. Because of that ability, the fixture expense and the work time are lessened massively. Overall, they are a convenient tool for working small repairs and have a lot of advantages in the industrial setting.

Only a bit investment in something as minimal can help industries get various perks when it comes to productivity.

If you look at the toggle clamp, you will discover a wide array of toggle clamps accessible in the market. Therefore, you choose to select the one which is best fitted to your industrial requirements. If you are one of those people who prefer to make the best of what’s accessible in the industry to make your work efficient and safe, this is one alternative that you must surely consider.

What’s more, you don’t need to spend a lot of cash on such type of clamps. What you need to do is to conduct some research before you make your decision for you to get the most out of it.

Factors to Consider When Choosing the Right Toggle Clamps

In this chapter, allow us to present you the essential factors you need to consider when selecting the ideal toggle clamps for your needs.

Clamp Action

In case you are wondering, there are four different clamp actions: squeezing, pulling, pushing and vertical.

Vertical Action Clamps

Here, the clamp bar has a central motion and clamps vertically down. In the vertical range, you will find three different styles.

oThe reverse clamp, wherein the clamp handle is at 250° to the clamp bar. A reverse clamp is also perfect in regions of restricted workspace because the clamp handle works at the tail of the clamp.

Horizontal Toggle clamp

wherein the clamp handle is at 180° to the clamp bar. Such are practical where space is restricted above the clamp because it’s fitted with a low profile handle.

The most widely utilized is also defined as the vertical clamp. This is where the clamp handle is at 90° to the clamp bar.

Push Action Clamps

These are clamp actions in which the plunger runs in a straight line. Such might be employed as a break or for a location and clamping or, when mounted vertically, as a press. The majority of the clamps toggle in both the rear and forward positions.

If you need the clamp to work as a precise locator, you should choose a clamp which has been made specifically for this application. You can also opt to the ones that combine the clamp along with a bushing arrangement. If you are working through a brush, care should be taken that the brush and clamp plunger are in line, or else the clamp might stick.

Pull-Action Clamps

These are also called as ‘latch’ or ‘hook’ clamps. These are perfect where fast precise locating of 2 parts is needed, like latching doors, clamping down, or clamping two halves of a mold. They work in either the horizontal or vertical plane. The clamps are provided with a double U bolt or single hook that is strung for modification. Various length hooks are accessible to fit specific applications.

Squeeze Action Clamps or Plier Clamps

Squeeze action clamps have a wide array of applications. This includes welding fabrication and sheet metal working.

Repeatability

For most applications, the repeatability of an average toggle clamp is enough. Nevertheless, in particular regions, the repeatability of the position of the clamp foot is pivotal to the entire operation. When the plunger or clamp arm is bringing a tightly toleranced location pin, your positional repeatability should be taken into consideration.

You see, vertical clamps on the majority of models have a few lateral bar guidance from the cheeks of the side plates. When the precision of your bar is crucial, then the bar must be supported by a hardened and machined tenon block.

In other applications though, acting as a precise location unit or carrying location pins, you must choose a clamp which has been designed specifically for location. An example of this is tight tolerance and fully bushed. It can also be that the location must pass through another bush.

Size of Your Toggle Clamp

The size of your toggle clamp is identified by:

The height under the bar

The distance needed from the clamp pivot to the clamping point

The number of space accessible for the clamp

The number of holding pressure or clamping force required

When standard clamps don’t suit your specific requirements, hooks, bars, clamp handles, or even the entire clamp can be tailored to fit a particular application.

Settling of the Clamping Pressure

It is very important whenever settling the clamping pressure not to over set your clamp for the comfort of the operation. That’s mainly because too much clamping force will cut the life of your clamp. What’s more, the clamping force might be modified by altering the spindle in the clamp bar or employing shims to increase and reduce the clamp body or under the clamp bar.

You also need to make sure that the clamp must be set, so the clamp is applied there’s a ‘light click’ as the linkages change into toggle position.

Number of the Clamps

Did you know that the number of your clamps could be measured by dividing the overall force needed by the clamping force or holding force of the chosen clamp? That’s true no matter if you use the clamping or holding force is dependent on the application.

Just take note that frequently, holding force values given are near to the body and will lessen the longer the clamping arm. If you are trying to identify the number of clamps, you always need to let a factor of safety and always round up the number of clamps needed.

Space

Following are the few things you need to consider when it comes to space:

Is there enough room to open your clamp or unload and load your component?

Can you perform the needed operations along with the clamp in position? For instance, is there enough access to the machining or welding operation?

Do you have any restrictions in the access or working area?

What reach do you need from the point of mounting to the clamping point?

What room have you got to attach the clamp?

How much space is accessible around your clamp?

Evaluating the space accessible for your clamp is crucial when identifying the kind of clamp needed.

The Ergonomics

Has consideration been presented to the clamp operator who might need to apply the clamp frequently that could result in health-related issues and fatigue? Following are some points you need to consider:

The clamping force is needed

The position of the clamp in connection to the operator. Is the clamp handle reachable? Is it in a position which permits it to be utilized routinely?

How much power does the operator need to apply to the clamp? Has the clamping pressure been set properly? You will find a lot of research done which present working guidelines to the amount of effort required to apply the clamp. Such things that need to be considered include the height of the clamp in connection to the operation as well as the effort required to apply the clamp.

For instance, 5.3 kilograms above the shoulder and 7.7 kilograms at shoulder height:

Is there a danger that hands or fingers will be stuck where the clamp is located? Is the operator at danger of pinching or trapping fingers or hands while working the clamp?

When a clamp is to be applied frequently, then the ease of the operator should be taken into consideration at all times.

You can prevent the danger of injury by employing a more proper sized clamp. These should be repositioning or extending the clamp handle or designing or modifying a particular for your application.

Manual or Pneumatic Clamps

Do you need pneumatic or manual clamps? The answer to this question will vary on different factors like:

Your budget

The availability of your clamp

The critical nature of your clamp to the operation

The frequency of your clamping cycles you need

The number of clamps you should use

Select for a manual clamp:

If the clamp should be accessible

If the clamp will operate occasionally

Select for an automated or pneumatic clamp:

If the clamp is vital to the operation or the quality of the product

If the clamp is to work at a great frequency

In case you are wondering, the majority of pneumatic clamps can have the facility to be applied manually and when released under power. That’s specifically practical if you want to position the parts precisely as the clamp closes. For instance, whenever clamping small brackets. However, you must be cautious of the Health and Safety impacts of pneumatically operated clamps.

The Durability

What type of clamp do you need: a light duty clamp, medium or heavy? You see, heavy-duty clamps typically have forged or cast handles, ground and hardened bushes and headed pins. The pins are more likely to be changeable as well.

Medium and light duty clamps are generally made from pressed components. They aren’t fully bushed at all times; they are less likely to have changeable pins.

If you are considering whether a heavy-duty clamp is needed, remember these tips:

The cost of the downtime must a clamp fail than the added expense of employing a heavy duty clamp

The setting the clamp will operate in and the probabilities that the clamp will be dented

Life of the tooling

The frequency of the operation

The clamping force needed

The Mounting Options

There are three options to attach a toggle clamp:

Front Mounted

The mounting face is at 90° to the clamp bar. That might be accomplished either through a clamp with front-mounting side plates, or when various heights are needed, through a template mounted clamp. It can also use a separate front mounting plate that permits heights to be different.

Template-Mounted

With this mounting options, the clamp fits over the blade. That might be a good advantage whenever you need the clamping point and mounting blade to be in line.

Base-Mounted

Here, the camp side plates are flanged and your clamp mounts flat to the ground/surface.

Clamp Detection

Is it crucial to your product quality or process that the clamp has been applied in keeps in position? In such applications, it’s possible to employ a manual clamp along with a built-in proximity switch that will sense if the clamp is locked.

Secondary Locks

Is it important to your application that the clamp keeps in the position either from a Health and Safety or functional perspective? Remember that toggle clamps are over center clamps which close. Nevertheless, in particular applications, especially with vibration, the clamp might come uncompleted.

When this is crucial, then a clamp along with a secondary clamp must be taken into consideration. That might either a secondary locking trigger or simple pin.

Coatings, Materials, and Environment

Every time is deciding which clamp is perfect for your application. You should consider the setting or environment your clamp will work in. Principally, toggle clamps are known to be zinc-plated mild steel, and the bulkier duty clamps are more likely to be chemi-blacked.

When the clamps can seize or rust, stainless steel clamps might be more appropriate. You also need to consider special industry requirements like in the pharmaceutical or food sector wherein Grade 316 stainless steel might be quantified. In extremely abrasive scenarios, aluminum might not be allowed.

When the clamps are going to be exposed to extremes, then lubricants or special cylinders might be needed. It might also be recommended to consider the effect of dissimilar materials.

When the clamps are being employed in a curing procedure and when there any limits about the fumes presented off from the clamps that might obstruct with the manufacturing procedure.

Component Thickness

Ask yourself: what is the thickness of your piece? Does it differ and by how much? Is an average toggle clamp appropriate for your application? Take note that a toggle clamp clamps to the similar position every time. Let’s say: if your component differs in thickness, then that difference could be accommodated by employing spring washers or springs under the clamp bar. Furthermore, the strength of the spring needed could be measured from the required clamping force.

On the other hand, when the variation is big, then you could contemplate employing a cam clamp. You see, cam clamps aren’t over center clamps locking clamps. Here, the clamp bar creates a cam, and they could take a few millimeters in thickness.

Clamping Feet

The kind of surface you’re clamping into will identify the type of clamp foot you need. If it’s important not to mark the surface, then you must employ a protective covering on the clamp foot. For instance, a neoprene cap or neoprene-tipped spindle which suits the bolt heat.

Typically, the neoprene-tipped spindle presents a safer and much longer lasting solution. These are also flat-bottomed generally, but if you’re clamping on a position, then you might prefer to consider neoprene spindles along with a semi-circular cross-section. Opting for this will lessen the likelihood of indentation.

When the clamping surface isn’t flat, you might require a self-leveling foot or swivel. Those also feature neoprene caps to safeguard the clamped surface.

If you’re clamping a complicated surface, and it is essential that your clamp complies to the profile, then you might need ‘mylars’ or ‘form blocks’ to compliment your component surface.

Clamp Bars

Typically, there are four various kinds of clamp bar accessible for vertical clamps, and they are:

Solid Bar

Solar bars are presented with a loose bolt retainer. Thus you might remove the clamp bar to the needed length and weld your bolt retainer.

S Bar

The clamping position of S Bar is permanent at pre-determined length. That kind of bar is most appropriate when it’s crucial that the clamping point keeps permanent or when a high clamping force is needed in which case the spindle might change in a ‘U’ bar clamp.

U Bar

This type of clamp bars enables the spindles to be changed in the clamp bar.

On other heavy duty models of clamps, some clamp bars are accessible with an array of tightly clearance holes and tolerance dowel that are punctured relative to the clamp mounting holes. That enables for Mylar blocks and fitting shims.

On the other hand, if you need a modified attachment or clamp arm, then you can opt for a heavy-duty ‘CH’ range. These are built to enable custom made arms to be mount easily and readily.

What’s more, any bar configuration might be presented openly on request.

Conclusion

No matter which type of toggle clamps you need, rest assured that you can find here at Roche Clamp! We are committed about clamps at Roche Clamp, but we also understand that they’re perhaps not the most thrilling piece of technology in your business.

However, they are an essential part of any product, process, or project. Selecting the perfect clamp for your needs will help you to bring on your schedules and promises in spite of the industry sector you’re in currently.

Click on any toggle clamp website, and you will be faced with a puzzling shopping list of clamps. Now, how can you place an order for something that you are not ever certain will fit your needs?

Roche Clamp wishes to help you pick the appropriate toggle clamps for your project, that is why we have created this e-book! We hope we simply help you navigate the often complicated, confusing realm of clamps. Our goal is to clarify toggle clamps so that you can choose the product you need and order it with so much confidence.

Now, are you ready to place an order with Roche Clamp? Visit our website today at https://www.rocheclamp.com/ to see our list of toggle clamps!

What are your thoughts about this guide? Share it with us by writing your comments!